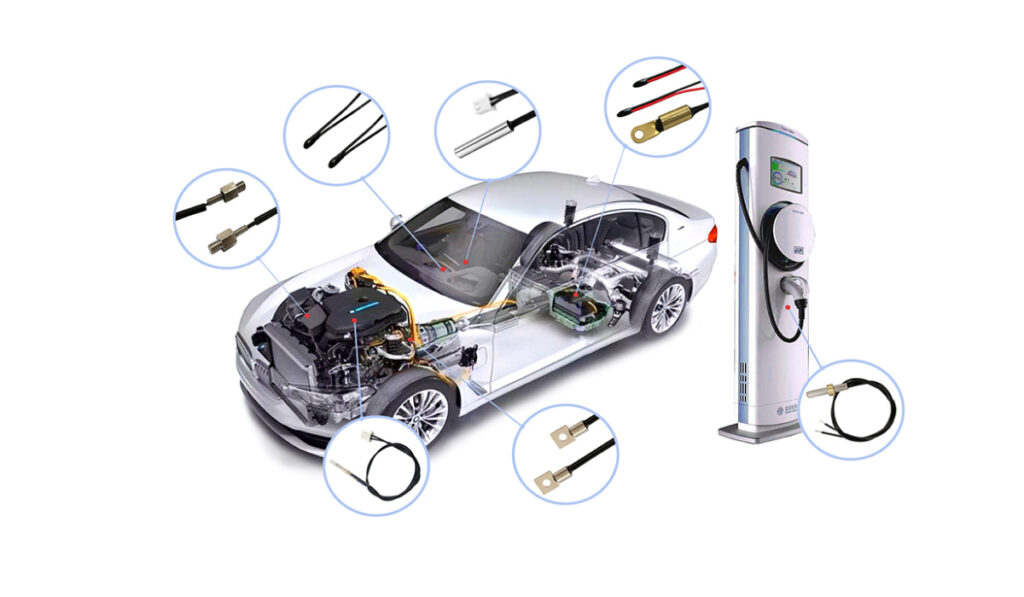

As the data source of the electronic control system in EV (electric vehicles) and HEV (hybrid vehicles), the NTC temperature sensor is a key component for the electronic control system, and one of essential technical parts being researched in this field. Besides the NTC temperature sensors for traditional auto parts, other NTC temperature sensors required for EV (electric vehicles) and HEV (hybrid vehicles) are used in driving systems, BMS, OBC, DC/DC, etc, for example, battery temperature detecting sensors, motor temperature monitoring sensors, battery cooling systems temperature sensors, and charging guns/piles temperature control sensors, etc.

- BMS battery temperature management system The battery management system (BMS) is similar to the “brain” in the entire security system of EV and HEV. It can estimate the charging state of the battery in real time, detect the state of the battery, and can directly monitor the battery control. For the “brain”, the more and more detailed feedback information is received, the more accurate the decision-making will be. In this case, the NTC temperature sensor has to be with high-precision and highly sensitive, so that the feedback data can be more comprehensive, and the BMS can judge the battery more accurately. The function as well as the working principle of the temperature sensor in the BMS is similar to that of the temperature sensor in the engine coolant of the traditional fuel vehicle, which is made according to characteristics that the resistance value of the ceramic semiconductor changes with temperature, and is used to detect the temperature of the vehicle battery. The best choice for BMS is NTC thermistor.

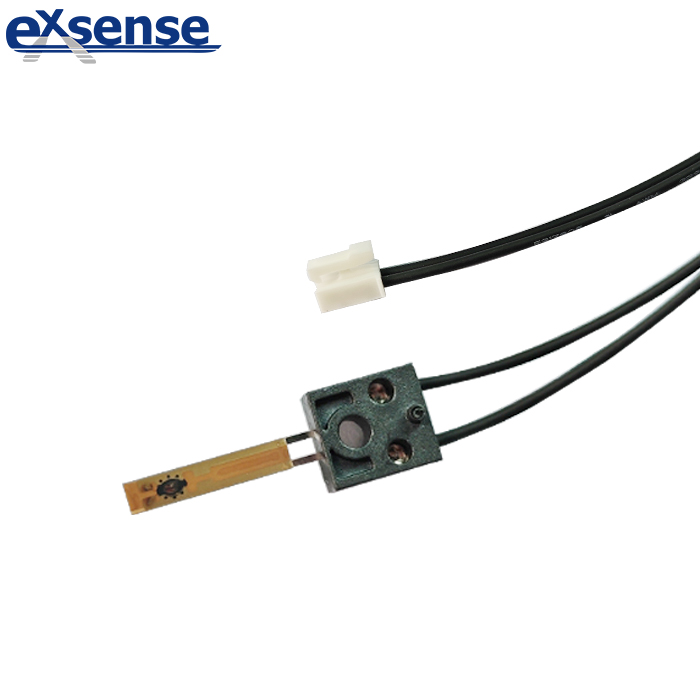

- Motor temperature management system The motor is the core component that converts electric energy into power for electric vehicles and hybrid vehicles. Thanks to the excellent acceleration performance and continuous work of electric vehicles, the internal temperature continues to rise, and the power level of electric vehicles is gradually increasing. By monitoring the temperature of the motor, the motor controller chooses suitable control strategies in different situations, in order to protect the entire power unit. Because the internal structure of the motor is compact, motor temperature sensor with characteristics like small size, high temperature resistance, resistance to harsh electromagnetic interference, high sensitivity, and high reliability is needed.

- The temperature control of the charging gun/pile Fast charging is one of the key elements to electric vehicles and hybrid vehicles’ promoting development. With the help of fast charging technology, time consumption can be reduced. However, fast charging needs to be realized by super-large current, additionally, pressure of the power and electronic equipment in the charging pile/gun will also increases. So temperature monitoring for fast charging in the gun/pile is very important. Meanwhile, when proceeding with fast charging, the connecting system between the charging pile and the car will also bear high temperature. To ensure safe monitoring of the car temperature and avoid overheating, it is critical to detect the temperature of the charging gun, charging pile and terminal block, and the IGBT module.

NTC temperature sensors for temperature monitoring are applied frequently in EV (electric vehicles) and HEV (hybrid vehicles). They are critical in EV and HEV.