As living standards improve, smart toilets are becoming increasingly prevalent. Most current smart toilets feature constant temperature cleansing functions, primarily relying on NTC temperature sensors within heating modules to maintain stable and safe water temperatures.

I.Working Principle of ConstantTemperature -Cleansing in Smart Toilets

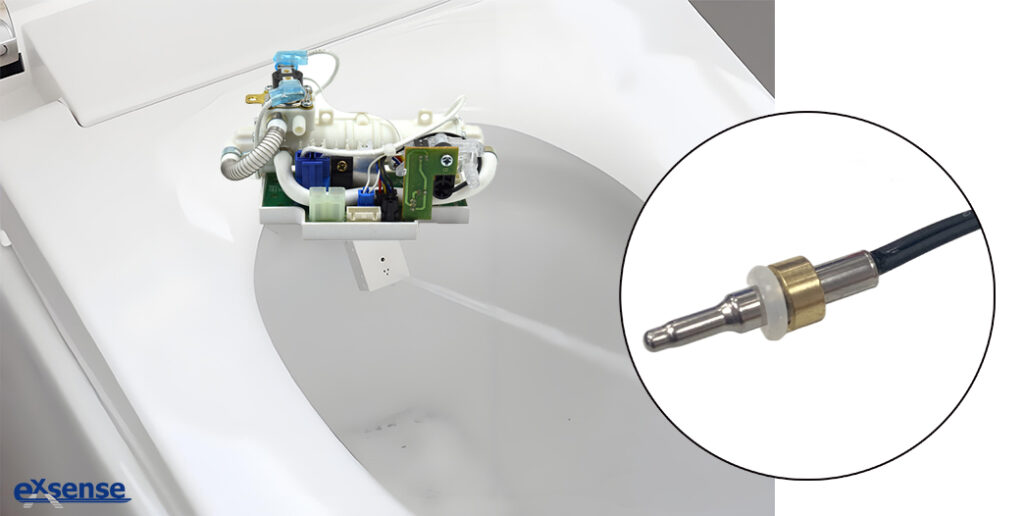

The constant temperature cleansing function is powered by an intelligent water heating system that precisely regulates water temperature through coordinated operation of water intake, heating, temperature control, and water delivery. Its core workflow involves seamless collaboration among the following components:

- Core Components

Instant Heating Mechanism: Rapidly heats water flow to meet immediate usage demands.

- Water Delivery Mechanism:

Connecting Pipe: Transports heated water between the heating module and water path switching components.

- NTC Temperature Sensor: Installed at the outlet of the connecting pipe to monitor water temperature in real-time.

- Water Path Switching Component: Directs water flow to specific outlets (e.g., bidet or feminine wash).

Control Mechanism:

- MCU (Microcontroller Unit): Coordinates water intake, heating, and water path switching.

- PID Controller: Adjusts heating power using ProportionalIntegralDerivative algorithms based on NTC sensor data for closed-loop temperature control.

- Water Intake Mechanism:Manages water flow via solenoid valves and pipes.

II.How NTC Thermistor Sensors Enable Precision Temperature Control

NTC Thermistor sensors play a pivotal role in three key aspects:

- RealTime Temperature Monitoring

Detects subtle temperature fluctuations (e.g., 0.1°C variations) at the outlet of the heating module.

Example: Ensures heated water consistently reaches preset temperatures (e.g., 38°C) during use.

- Safety Protection Mechanisms

Triggers alarms and shuts off heating power if temperatures exceed safety thresholds (e.g., 50°C), preventing scalding risks.

III. Key Considerations for NTC Sensor Selection

For innovative toilet applications (target range: 25–40°C, response time: 0.6–1 sec), prioritize:

- Response Time

EXSENSE’s bullet-type series achieves 0.3-second response times, exceeding industry standards.

- Temperature Accuracy

±1% precision to avoid discomfort from temperature deviations.

- Resistance and B Value

Standard R25℃: 10K, 50K, or 100Ω.

B Value: 3435, 3470, 3950, or 3977 for optimal linearity.

IV.Structural Design and Environmental Adaptability

- Compact Packaging

EXSENSE’s cylindrical bullet-type sensors (3–5mm diameter) suit confined spaces and support flexible installation.

- Water Resistance

Ensures durability in humid environments with IP67 or higher waterproofing.

Conclusion

As the core component of innovative toilet temperature control systems, EXSENSE’s temperature sensors enable dynamic thermal balance and safety through real-time feedback and PID algorithms. This technology elevates user comfort while showcasing the critical role of NTC sensors in advancing smart home innovation.