Ⅰ.What is IGBT?

The IGBT (Insulated Gate Bipolar Transistor) is a core component in power electronics, often hailed as the “brain—control “centre of modern energy conversion systems. By integrating the technical advantages of Bipolar Junction Transistors (BJTs) and Metal Oxide Semi conductor Field Effect Transistors (MOSFETs), a driven power semiconductor device is formed.

Ⅱ.Consequences of Operating IGBT Without Temperature Control

In new energy vehicles, the IGBT module is a critical component. Controlled via three terminals—Gate (G), Emitter (E), and Collector (C)—it is widely used in devices like converters and inverters. The primary heat source in converters is the IGBT module, which generates heat during switching operations due to changes in frequency. Excessive temperatures (typically greater than 150°C) can cause device failure. Thus, an NTC thermistor probe must be installed to monitor module temperature in realtime, prevent operation near critical thresholds, trigger rapid safety protections, and avert thermal runaway.

III. How NTC Thermistors Enable IGBT Temperature Control

- Effective Temperature Monitoring

NTC thermistor probe continuously monitor the core temperature of IGBTs during prolonged operation. For example, installed in EV converters and inverters, they provide realtime feedback on substrate temperature, enabling dynamic adjustment of IGBT power output to prevent overheating.

- Thermal Management Optimization

In photovoltaic inverters, NTC thermistor sensor monitor temperatures across multiple IGBT modules. The MCU system dynamically adjusts cooling fan speeds based on temperature data to balance module loads and minimize excessive wear and tear. If a module’s temperature exceeds 110°C, the system automatically switches to a backup module or reduces its current output to prevent localized overheating.

Ⅳ.NTC Thermistor Installation Methods

- Direct Mounting on IGBT Substrate:

Secure the NTC thermistor sensor to the IGBT module’s heatdissipating substrate (near the chip) using thermal paste or soldering. This ensures efficient thermal coupling and minimizes temperature measurement lag.

2.External Heat Sink Monitoring:

If the module lacks a builtin NTC, attach the thermistor to the heat sink surface. Note that thermal resistance between the chip and heat sink may cause measurement errors, suitable for less precisioncritical applications.

Ⅴ.Application Scenarios

1.Industrial Converters:

NTC thermistor sensor mounted on IGBT substrates block PWM signals via PLCs or driver boards when temperatures exceed 120°C, preventing thermal damage.

2.EV Motor Controllers:

Builtin NTCs monitor IGBT temperature in realtime. Integrated with the Battery Management System (BMS), they enable thermal balancing control and reduce motor power output in the event of overheating.

3.Photovoltaic Inverters:

Multiple NTCs monitor temperatures across IGBT modules. The MCU activates redundancy protocols—switching to backup modules or derating operation—if any channel overheats.

Ⅵ.Recommended NTC Thermistor Models

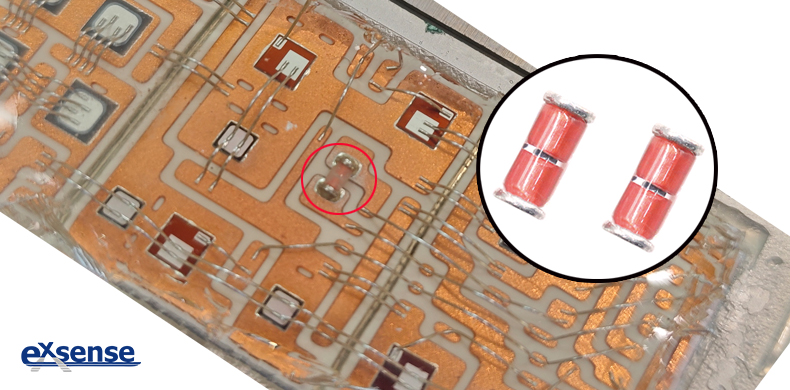

EXSENSE’ independently developed solderable MELF glassencapsulated NTC thermistors feature Dumet wire leads and a highpressure glasssealed chip, offering hightemperature resistance (up to 250 °C) and waterproofing. Widely used in IGBT modules, EV control systems, PV inverters, and household appliances.

Key Parameters:

- Resistance: 5kΩ ±1%

- Bvalue: 3375 ±1%

Custom specifications are available upon consultation.

Conclusion

NTC thermistor prode enable highprecision, reliable thermal control for IGBT modules by converting “temperature resistance electrical signals.” Practical applications require selecting NTC parameters based on IGBT power ratings, operating environments, and cooling conditions. For modulespecific designs, consult technical experts for optimal selection.