The automotive PTC heater is a typical heating device in vehicle air conditioning systems. It uses electrical heating to supply warm air to the cabin, ensuring passenger comfort in cold weather. During rapid operation, the PTC heater requires an NTC temperature sensor to monitor internal temperatures, preventing overheating and component damage.

How PTC Heaters Work

A PTC heater transfers heat generated by its heating core to a radiator frame, then disperses the heat through fins. Heat is carried away as airflow passes over the fins, producing warm air. Currently, PTC heaters employ two cooling methods: liquid and air. Liquid cooling systems provide stable heat dissipation and precise temperature control across varying environmental conditions and are more widely adopted in mid-to-high-end electric vehicles.

Structure of the PTC Heater’s Water Channel

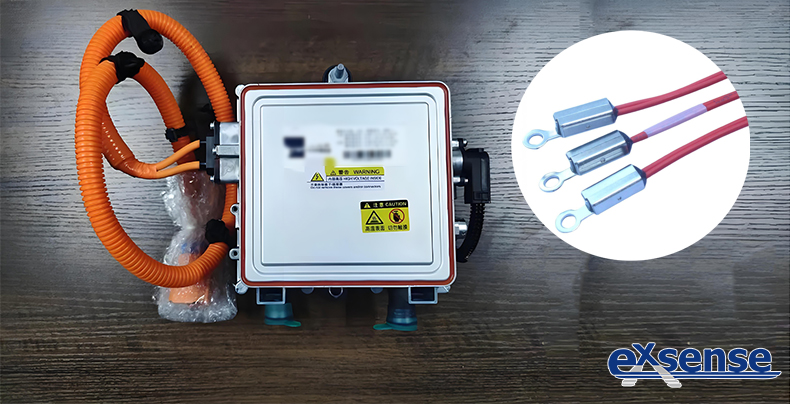

The PTC heater’s water channel structure includes a base plate and a heater housing. The base plate houses the heater, while the housing contains internal water channels with inlet and outlet ports. NTC temperature sensors are installed on the inner walls at the start and end points of the water channels to monitor fluid temperatures at the inlet and outlet, enabling real-time evaluation of cooling efficiency.

How do NTC Temperature Sensors Interact with PTC Heaters?

1.Temperature Monitoring & Feedback Control

- Real-time monitoring: NTC temperature sensors continuously track the PTC heater’s internal temperature, providing real-time data to the control system. This allows dynamic adjustment of heating power to maintain temperatures within set parameters.

- Feedback control: By comparing sensor data to preset values, the control system adjusts current input (e.g., via PID control) to achieve precise temperature regulation and minimize fluctuations.

2.Overheat Protection

- Threshold triggering: If the NTC detects temperatures exceeding safety limits, it sends a signal to the Electronic Control Unit (ECU) to cut power or activate cooling measures. During system faults (e.g., poor heat dissipation), power reduction or shutdowns are triggered to prevent fire hazards or component damage.

3.Energy Efficiency Optimization

- On-demand heating: Leveraging precise NTC feedback, the PTC heater operates only when necessary, reducing energy waste. In electric vehicles, this extends the battery range.

Application Scenarios for NTC Temperature Sensors

- Cabin heating: Replaces traditional fuel-powered heating in EVs, with NTCs ensuring safe and efficient heater operation.

- Battery thermal management: Activates PTC heating for batteries in cold conditions, while NTCs prevent overheating to extend battery lifespan.

- Auxiliary heating: Enables rapid heating for seats, steering wheels, etc., with NTCs balancing comfort and burn prevention.

Conclusion

NTC temperature sensors act as “guardians” in automotive PTC heaters, ensuring system safety and reliability while enhancing energy efficiency and user experience through intelligent control. Their synergy with PTC components highlights the sophisticated design of vehicle thermal management systems, balancing safety redundancy and precision control.