Against the backdrop of intensifying global energy crises and growing environmental awareness, solar photovoltaic (PV) energy, a zero-pollution renewable resource, is emerging as a focal point in the energy sector due to its sustainability and clean attributes. Home photovoltaic energy storage systems, as core components of solar power generation, directly impact solar energy conversion efficiency and power supply stability. With technological advancements and industrial development, PV energy storage and reuse systems are rapidly entering ordinary households.

However, maximizing photovoltaic energy utilization, enhancing storage efficiency, and improving safety remain critical challenges for the industry. Leveraging their high sensitivity and rapid response characteristics, NTC temperature sensors enable real-time, precise monitoring of temperature changes in key modules of energy storage systems. This effectively mitigates overheating risks and ensures the safe, stable operation of home PV energy storage systems. Below, we explore how NTC temperature sensors function in these systems through their working principles, module composition, and practical applications.

I.. Principles and Module Composition of Home PV Energy Storage Systems

A home PV energy storage system operates through four stages: power generation, current conversion, energy storage, and power consumption. These stages involve collaboration among multiple components, including:

- Solar panels(light energy harvesting),

- Inverters(DC-to-AC conversion),

- Battery Management Systems (BMS)(energy storage modules),

- Controllers(load management),

- MCUs(microcontroller units).

Working Principles:

- Power Generation Stage

- Solar panels convert sunlight into direct current (DC) via the photovoltaic effect. Semiconductor materials in the panels absorb photon energy, freeing electrons to generate an electric current.

- Conversion Stage

- Household appliances typically use alternating current (AC). Inverters convert the DC output from solar panels into AC to meet home electricity demands.

- Storage Stage

- Batteries store excess electricity generated during periods of low household demand. Controllers monitor battery parameters (e.g., charge level, voltage, and temperature) to ensure safe charging/discharging and prolong battery lifespan.

- Power Consumption Stage

- During low sunlight or nighttime, stored energy from batteries is discharged. The DC from batteries is converted back to AC via inverters to power home appliances.

II. NTC Temperature Sensors in Key System Components

NTC (Negative Temperature Coefficient) thermistors are widely used in home PV energy storage systems for temperature monitoring and safety optimization. Key applications include:

- Energy Storage Batteries

- Installation: Multiple NTC sensors (often dozens per battery module) are mounted on battery surfaces to monitor internal temperature distribution.

- Function: Batteries generate heat during charging and discharging. Overheating accelerates aging, reduces lifespan, and poses safety risks.

- Example:

- When battery temperature exceeds a threshold (e.g., 45°C), the BMS reduces the charging current (e.g., from 10A to 5A) to prevent damage.

- In low temperatures (e.g., <0°C), the BMS adjusts discharge cutoff voltage (e.g., from 2.5V to 2.8V) to avoid over-discharge.

- Inverters

- Installation: NTC sensors monitor the temperature of power components (e.g., IGBTs).

- Function: Overheating protection for critical components.

- Example:

- At 80°C, the controller reduces the inverter output power to limit heat generation.

- NTC data regulates cooling fan speeds: low speed at lower temperatures and higher speed as temperatures rise.

Summary: NTC sensors play vital roles in temperature monitoring, safety protection, and performance optimization for batteries and inverters.

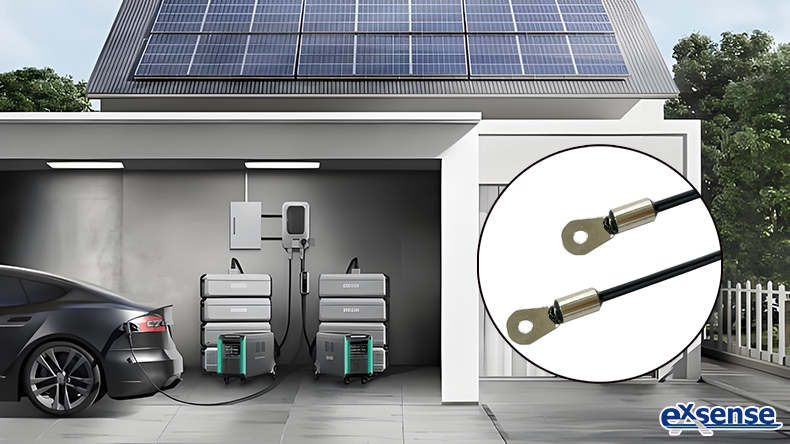

Recommended NTC Sensors for Home PV Energy Storage

The Dihuantou Metal Series NTC temperature sensors (developed by EXSENSE) feature:

- Material: Nickel-plated brass encapsulation.

- Advantages: High stability and mechanical durability.

- Specifications:

- Accuracy: ±1%, ±2%.

- Resistance options: 10KΩ, 50KΩ, 100KΩ.

- B-value options: 3435, 3470, 3950, 3977.

Installation: Fixed via screws or laser welding onto surfaces of components such as inverters, BMS modules, EV charging piles, and PDU/OBC systems. Customizable ring terminal sizes are available.

Conclusion

NTC temperature sensors are indispensable for ensuring the stability, safety, and longevity of home PV energy storage systems. As renewable energy storage technologies evolve, these sensors will play an increasingly expansive role.