I.Working Principle of NTC Thermistors

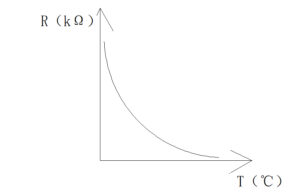

NTC (Negative Temperature Coefficient) thermistors, widely used as temperature-sensitive components, are typically fabricated by precisely mixing and high-temperature sintering transition metal oxides such as manganese, cobalt, nickel, and copper. Their core functionality lies in their NTC characteristic: as the ambient temperature rises, the concentration of charge carriers within the material increases, causing the resistance to decrease exponentially. Conversely, resistance rises as temperature drops. By measuring resistance changes via precision circuits and applying mathematical models with calibration parameters, the temperature of the measured object can be accurately determined.

Thanks to their high sensitivity, rapid response (as fast as 0.3 seconds), high precision, and excellent stability, NTC thermistors play critical roles across industries:

- Energy Vehicles: Monitoring battery pack temperatures to ensure safe charging/discharging.

- Smart Home Devices: Precisely controlling water temperatures in coffee makers and smart toilets.

- Office Automation: Monitoring fuser temperatures in printers.

- Aerospace/High-Speed Rail: Ensuring stable operation under extreme conditions.

II.Advantages and Limitations of NTC Thermistors

- Key Advantages

Rapid Response: Detects subtle temperature fluctuations (as small as 0.1°C) and instantly converts them into electrical signals, ideal for time-sensitive applications.

High Stability: Maintains performance under harsh conditions (e.g., high temperatures, humidity) with minimal parameter drift during thermal cycling.

Compact Design: Miniaturized structure enables integration into compact devices like smartphones, wearables, and precision instruments.

High Accuracy: Advanced manufacturing achieves ±0.05°C temperature precision and resistance tolerances of ±0.5%, ±1%, or ±2%, supporting precise temperature control.

- Limitations

Temperature Range Constraints: The standard operating range is 40°C to 420°C, which may fall short in ultrahigh temperature applications. However, advancements in material science are expected to expand this range.

III. Application Fields of NTC Thermistors

- Energy Vehicles

Monitor IGBT module temperatures to prevent overheating.

Optimize battery charging/discharging strategies via BMS integration.

Ensure thermal stability in charging piles, PTC heaters, and OBC modules.

- Smart Home Devices

Regulate water temperatures in coffee machines and smart toilets.

Monitor battery/motor temperatures in robotic vacuums.

- Office Automation

Stabilize fuser temperatures in printers to prevent paper jams or image blurring.

- Aerospace/HighSpeed Rail

Monitor temperatures in transformers and capacitors to prevent system failures.

- Temperature Measurement Instruments

Enable rapid, noncontact medical thermometers and industrial sensors.

IV.Installation Methods and Storage Guidelines

(1) Installation Methods

- Direct Soldering

Solder pins to PCBs using a temperature-controlled iron (260–300°C). Limit soldering time to <3 Seconds to avoid thermal damage.

Ensure clean, oxide-free pins and adequate PCB spacing for heat dissipation.

- Encapsulated Sensor Mounting

Fix sensors to surfaces using screws, clamps, or high-temperature adhesives.

For liquid, fully immerse the probe and seal joints to prevent leaks.

Thermal paste is applied between sensors and solid surfaces to enhance heat transfer.

(2) Storage Precautions

Avoid direct sunlight, moisture, and corrosive environments. Store in dry conditions (<60% humidity).

Use sealed, desiccant-packed bags for long-term storage.

Keep away from strong magnetic fields and corrosive gases.

NTC thermistors are indispensable for precise temperature control across industries. Proper installation and storage ensure their reliability and longevity in demanding applications.