Acting as the “sensory nerve endings” of the battery thermal management system, NTC temperature sensors are strategically embedded within the battery to monitor real-time temperature, ensuring stable operation within a controlled range during charging/discharging.

Against the backdrop of escalating global energy crises and environmental pollution, the energy vehicle (EV) industry has emerged as a worldwide focal point with unprecedented momentum. The traction battery must deliver efficient, high-power discharge capabilities as the core component of an electric vehicle’s power system. However, the battery generates significant heat during actual operation, charging, and discharging, leading to a sharp rise in temperature. Notably, the charging/discharging rate exhibits a clear positive correlation with the battery’s thermal power and temperature increase: the faster the rate, the higher the heat generation and temperature rise. This phenomenon not only directly impacts battery performance and lifespan but also poses potential threats to the safety and reliability of electric vehicles.

I. Why Is Battery Temperature Control So Critical?

As the “heart” of an energy vehicle, the performance of the traction battery directly determines the vehicle’s range and safety. Extreme temperatures—whether overheating or overcooling—significantly compromise both range and safety. Under high-temperature conditions, internal battery temperatures can surge rapidly, causing severe performance degradation and triggering “thermal runaway,” which may lead to catastrophic events like fires.

Acting as the “sensory nerve endings” of the battery thermal management system, NTC thermistors are strategically embedded within the battery to monitor real-time temperature, ensuring stable operation within a controlled range during charging/discharging. Research indicates that the optimal operating temperature for traction batteries is 15°C to 35°C. Prolonged exposure to temperatures above 45°C under high-rate charging/discharging conditions can reduce cycle life by approximately 60%. Chronic high-temperature operation also risks localized overheating, excessive cell-to-cell temperature differentials, and heightened thermal runaway risks. Therefore, precise temperature and differential control—ensuring uniform heat dissipation and temperature consistency across the battery pack—is vital for maximizing performance, extending lifespan, and safeguarding NEV safety.

II.NTC Temperature Sensors: The Intelligent Guardians of Battery Thermal Management

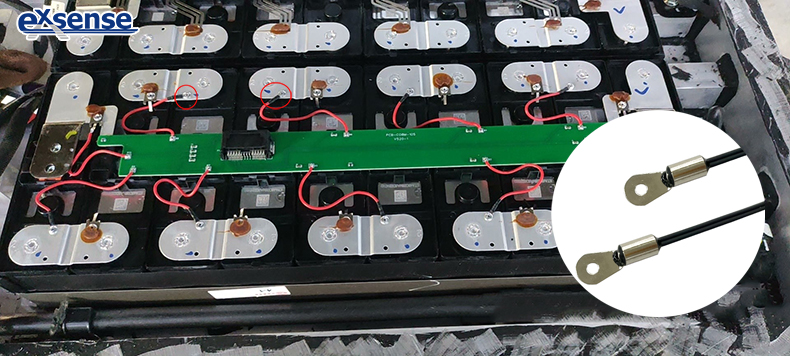

NTC temperature sensors are installed at critical positions within the battery pack, such as between individual cells or module surfaces. Their probes are precisely welded to temperature sampling boards, while their heads are secured to module surfaces via screws. These sensors work with the Battery Management System (BMS) to enable precise temperature regulation and overheating Protection. Currently, air and liquid cooling dominate battery thermal management technologies, aiming to maintain optimal operating temperatures. Below is a detailed breakdown:

- Temperature Monitoring

During high-power operation, battery modules inevitably generate substantial heat. NTC thermistors sensor continuously track temperature changes at module cores and relay anomalies to the control unit. Upon receiving signals, the unit triggers rapid responses—such as increasing coolant flow rates or activating air cooling—to dissipate excess heat and stabilize temperatures. Similarly, the system provides heating in low-temperature environments to ensure regular battery operation.

l Air Cooling: Utilizes airflow to remove heat generated during battery operation.

l Liquid Cooling: Employs circulating coolant within the battery pack to absorb and dissipate heat.

- Overheat Protection

When an NTC sensor detects temperatures exceeding the safe range (consistently above 45°C) or approaching thermal runaway thresholds (60°C), it immediately alerts the BMS. The BMS then initiates a multilevel response:

– Cut power output from overheating modules and switch to backup modules to ensure uninterrupted vehicle operation.

– Dual-control strategy:

– Reduce discharge current to slow internal chemical reactions and minimize heat generation.

– Activate enhanced cooling (e.g., high-speed fans, accelerated coolant circulation) to maximize heat dissipation.

III. Key Considerations for NTC Temperature Sensor Selection

Selecting NTC thermistor Prodes for automotive batteries requires evaluating multiple factors:

- Accuracy: Precise temperature measurement is critical for BMS to assess battery status and implement effective thermal control. Automotive-grade NTC sensors typically require an accuracy of ±0.5°C to ±1°C.

- Stability & Reliability: Sensors must endure diverse environmental conditions throughout the vehicle’s lifecycle. Rigorous testing—including high-temperature aging, humidity resistance, and vibration tests—is mandatory to ensure compliance with automotive standards like ISO 16949.

- Response Time: Rapid detection of temperature fluctuations is essential for proactive thermal management.

- Durability: Resistance to chemical corrosion, mechanical stress, and thermal cycling ensures long-term performance.

By addressing these factors, NTC temperature sensors can effectively safeguard battery performance, longevity, and safety in the demanding environment of energy vehicles.

For inquiries regarding additional specifications or customized product solutions, please consult EXSENSE. Our engineering team will collaborate closely with your company to tailor NTC temperature sensors to your application requirements, ensuring optimal performance and reliability for your battery thermal management systems.